Add: Tongji Industrial Zone,JimoQingdao China 266228

Mobile: 86-18653233625 (WhatApp, WeChat)

E-mail: info@segerindustrial.com

Tel: 86 532 68893719

Fax:86 532 85698271

Excellent quality,economical and good products,first-class service help Seger Foundry to win a great deal of consumers’ favor.Under ISO9001:2008 quality management system,to ensure the quality of orders, our independent QC members carry out strict inspection at each stage with our own professional measuring tools and inspection equipment :

Before pouring,100% chemical component test with the spectrometer

Mainly include A.Tensile strength test B.Yield strength test C.Test of elongation D.hardness test etc

Normally,100% full test for key dimensions and spot checking for other dimensions

Microstructure inspection

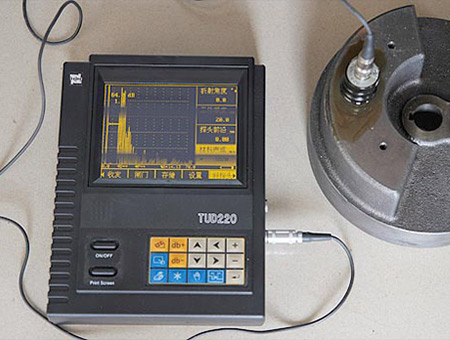

Ultrasonic inspection

Magnetic powder inspection

100% checking before packing

Before shipment,each quality problem will be solved in every production stage and all parts have to pass our strict internal inspection.To satisfy different client’s requirement,the third party inspection also be welcomed.

We can support follow test.

1) chemical component and raw material testSpectrograph

2) Mechanics Performance Test

Tensile strength test and Hardness test

3) Dimension test

Three coordinate detector ,Gauge test,

4) appearance inspection surface quality check

5) Inside quality inspection magnetic powder inspection and ultrasonic flaw detection

6) Third part test report.